The working principle of precision flat steel production process flat steel finishing machine is to pre level and finally level the cold flat steel wool with two groups of leveling wheel sets arranged alternately up and down in the thickness direction; A pair of finishing wheels arranged relatively are used to extrude the width direction, so that the width is compressed to achieve the expected parameters, and the compression amount is adjustable; Straighten the width with 5 staggered straightening wheels. The system is mainly composed of control box, finishing roller, pre leveling unit, finishing unit and straightening unit.

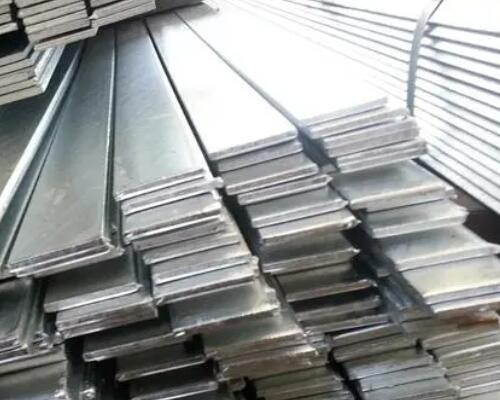

The production process can be summarized as follows: pre leveling → finishing → straightening → post leveling. Flat steel / A / B steel with width of 12-300mm, thickness of 4-60mm, rectangular section and slightly pure edge. Flat steel can be finished steel, or it can be used as blank for welded pipe and thin slab for laminated thin plate. Main uses: as a finished material, flat steel can be used to make hoop iron, tools and mechanical parts, and used as building frame structural parts and escalators in buildings. Flat steel can be divided into two types according to its shape: flat spring steel and single side double groove spring steel. Hot rolled spring flat steel is mainly used to manufacture leaf springs in automobiles, tractors, railway transportation and other machinery.

— 电 话:0315-5327902

— 传 真:0315-5327902

— 邮 箱:sale@rentaisteel.com

— 地 址:Qian'an Economic Development Zone, Hebei Province

— 邮 编:063000

扫码关注